You are having problems in your home that only insulation can fix, but hiring the wrong contractor can lead to even bigger problems. Opting for the cheapest option isn’t always the best choice, as it can result in significant costs for dealing with the aftermath of a poorly executed job.

Hiring a good contractor is big; choosing the wrong person could make your home insulation project a disaster. Here are things to look for and where most cost variations happen from one contractor to another.

Insurance:

First and foremost, Liability and Workers Comp. These insurances are not just for the contractor to have; they protect you and your property as a customer. Any reputable and responsible contractor or company would proactively make sure that you and they are covered.

Equipment Used & Knowledge of It:

Knowledge of the equipment is crucial because installers need to regulate the settings on the equipment to ensure the quality of the final product. Proper calibration and adjustment of tools and machinery directly impact the effectiveness and longevity of the insulation. By mastering their equipment, installers achieve optimal insulation performance and installation quality, making sure that you get what you expect and more.

Another fact to consider for North East PA, about 70% of Spray Foam contractors will require “plugging” into your electrical panel, so-called “shore power.” While using the homeowner’s power might result in a lower job bid, it’s essential to weigh this cost savings against the potential risks and liabilities. Homeowners should consider whether the lower bid is worth the potential hassle and risk of using their electrical system.

Building Science:

This is a vital aspect of insulation work. It’s the understanding of a building as a complete system, with the aim of enhancing air quality, energy efficiency, and comfort. This is a topic we delve into deeply every day, and it’s essential knowledge for every insulation contractor. For instance, an improperly insulated attic can accumulate so much moisture that it fosters mold growth, potentially damaging the structural integrity of your home.

Insulators with a background in construction often have a better understanding of the impact insulation will and can have on a building. Their construction experience provides them with insights into how different building materials and structural elements interact with insulation, air infiltration, and moisture. They can foresee potential challenges and understand how insulation contributes to the overall efficiency, durability, and comfort of a building. This knowledge allows them to make more informed decisions, ensuring that the insulation is installed correctly and effectively, ultimately enhancing the building’s performance and energy efficiency. These insulators will work with builders and architects to advise on key design elements, long-term benefits, and cost-effectiveness of choices.

Materials Used, Quality, & Knowledge of the Materials:

Most spray foam manufacturers and conventional insulation manufacturers do not sell directly to contractors directly they use distributors. However, the manufacturer aspect is important as not every manufacturer is the same, and the raw materials vary in quality, performance of the installed product, and the manufacturer’s warranty for raw products. It’s crucial for spray foam and insulation contractors to have a deep understanding of the raw materials they work with for several reasons:

Safety:

Knowing the properties of raw materials helps ensure safe handling and application. Some materials may be hazardous if mishandled or improperly mixed, leading to potential health risks for both the contractors and the occupants of the spaces where foam is applied.

Quality Control:

Understanding the characteristics of raw materials allows contractors to maintain consistency and quality in their work. This includes proper mixing ratios, temperature considerations, and understanding how different environmental conditions might affect the application process.

Optimal Performance:

Different formulations of spray foam are designed for specific applications and environmental conditions. Contractors need to know which raw materials are suitable for particular projects to ensure optimal performance and longevity of the insulation or sealing.

Overselling & Underselling:

Many salespeople will try to push for more. More is not always better, and usually less cost-effective for you. We work through the solution that is right for you, starting with identifying the problem that needs to be solved and working through the steps towards solving it and bettering your home and health.

Underselling might indeed be a bigger issue than overselling, especially in a market where a residential customer is not considered a repeat customer.

When salespeople push for less expensive projects, there’s a significant risk that the solutions offered may not align with the homeowner’s specific needs and goals. With this, you may end up with a solution that doesn’t fully meet your needs and over time might need to invest more to upgrade or replace the undersold solution, leading to higher cumulative costs.

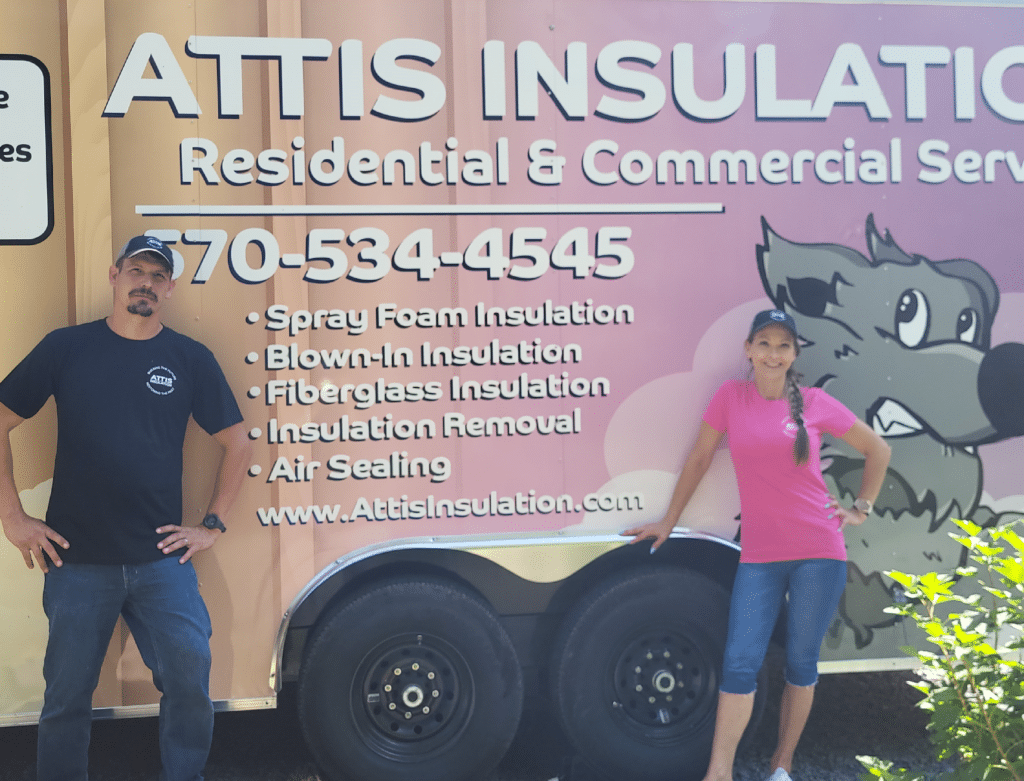

For Attis Insulation, trust is a critical component of local business relationships. We don’t have dedicated salespeople, and from the moment you call us, you are speaking to a field expert. Our goal is to build solutions that genuinely solve homeowners’ problems, even if it means recommending a more expensive option. We are focusing on long-term value rather than immediate gains.

When looking to invest in insulation, an ideal contractor will have experience working with a variety of materials, building codes, and have the appropriate insurance in place. Insulation is not a job for a general handyperson. Insulation must not only abide by local regulations, but it also needs to be tailored to each home’s needs and design. A professional insulation contractor is well-versed in all the specifications and regulations and will ensure your insulation is expertly installed.

Want to talk to the experts who meet all the criteria above? Contact Attis Insulation today for a free estimate!